Rapid prototyping

Designeering offers rapid prototyping for products where we’ve been involved in the concept design and CAD engineering.

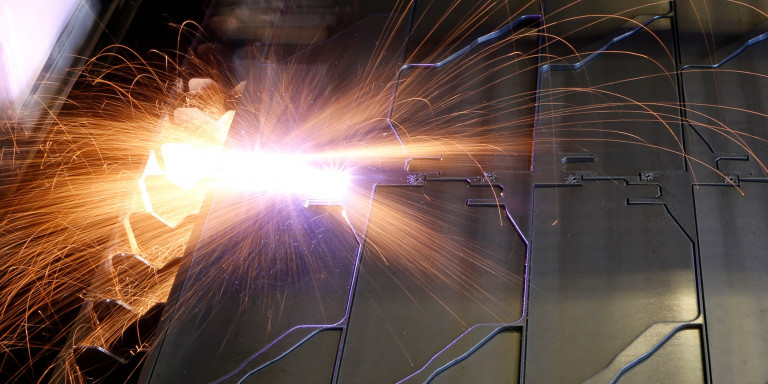

Rapid prototyping is the fast fabrication process of a physical part that has been created with 3D CAD. We can use 3D printing, laser cutting or many other machining techniques, without the need for additional machine setup. It’s one of the fastest and most cost-effective ways to create prototypes.

The rapid prototyping process allows us to create even the most complex designs in a fraction of the time it would take using traditional methods. And with very little waste.

3D printing services

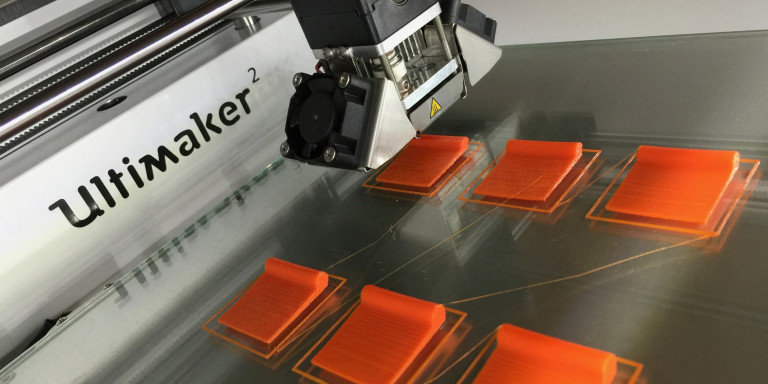

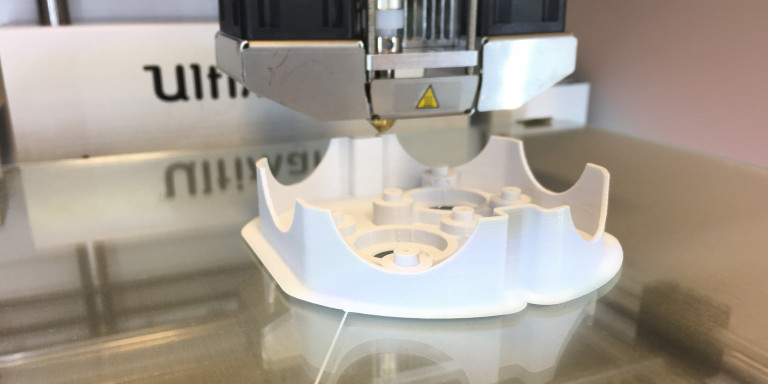

3D printing, also known as additive manufacturing, is a quick way of producing parts and components from a 3D CAD. The 3D printing process can take several forms, depending on the item you need.

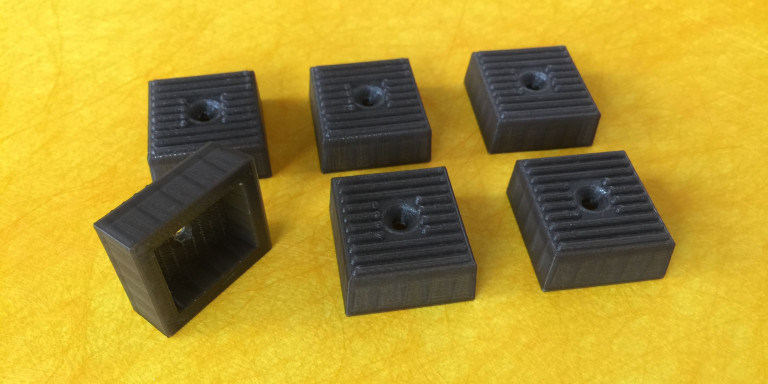

Our studio is equipped with a professional FDM printer or more precisely Fused Deposition Modelling printer. FDM is a 3D printing additive manufacturing process. It works by extruding thermoplastic filaments, such as PLA or ABS, through a heated nozzle. The nozzle melts the thermoplastic and applies it layer by layer to create a 3D object.

Other 3D printing processes allow us to make parts in a wide range of plastic materials, flexible polymers, metals and even ceramics. The process we use will depend on the part you need creating.

Prototype modelling

For more complex and complete products, where 3D printing might not be an option, we can use more traditional forms of prototype modelling. While these take longer to produce, they will often give you a superior result.

A well-made prototype will help with testing and refining your design. Further down the line, a working prototype will help you demonstrate your product to potential buyers and investors.